Peka‑Pro SL is part of Peka Chemie’s high‑performance Fusion Bonded Epoxy product line. Designed as a single layer system, it provides reliable corrosion protection and durability for pipeline transportation systems in oil, gas, and water industries. This solution balances cost‑efficiency with compliance to stringent international standards.

Key Advantages:

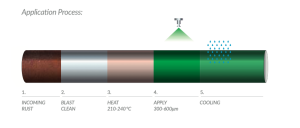

Application Process:

Technical Features:

| Property | Test Method | Acceptance Criteria | Results |

|---|---|---|---|

| Color | — | — | Green & Gray |

| Gel time @ 205°C | ISO 21809‑02 (A.3) | — | Available in 4 types |

| Impact Resistance | ISO 21809‑02 (A.14) | ≥ 2 J | Pass |

| Cathodic Disbondment | ISO 21809‑02 (A.9) | 24 h, –3.5 V, 65°C ≤ 5 mm <br> 28 d, –1.5 V, 20°C ≤ 8 mm <br> 28 d, –1.5 V, 65°C ≤ 18 mm | 1–4 mm <br> 1–3 mm <br> 6–9 mm |

| Flexibility @ –30°C | ISO 21809‑02 (A.13) | No cracking @ 2° ppd | Pass |

| 28 d Hot‑Water Adhesion (75°C ± 3°C) | ISO 21809‑02 (A.16) | Rating of 1 to 3 | Rating 1 |

| Taber Abrasion Resistance | ISO 21809‑02 ASTM D4060 | 100 mg | 35 mg |

International Standards Compliance:

Best For:

© 2025 – All rights reserved – Powered by Ravak Agency