Peka‑Pro DL‑UF from Peka Chemie is a specialized dual‑layer FBE coating system designed to meet or exceed the CSA Z245.20‑22 System 2A flexibility requirements. This coating is formulated for pipeline sections that must undergo significant bending during installation — such as when navigating terrain changes, river crossings, or challenging alignment profiles.

By combining the proven Peka‑Pro Pr primer layer for corrosion resistance with a specially modified ultra‑flexible FBE topcoat, DL‑UF ensures that pipes can be bent further than with conventional FBE systems, even at higher film thicknesses. This flexibility is achieved without sacrificing adhesion, abrasion resistance, or long‑term durability.

Key Advantages

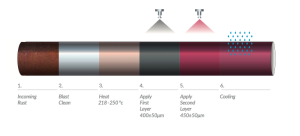

Application Process

Technical Highlights (Representative for DL‑UF System)

| Property | Standard | Result |

|---|---|---|

| Color | — | Red |

| Gel Time @ 205 °C | IGS‑M‑TP‑026 | Available in 4 types |

| Impact Resistance | IGS‑M‑TP‑026 | Pass |

| Cathodic Disbondment (48h, 80 °C) | ≤ 5 mm | 1–4 mm |

| Cathodic Disbondment (28d, 20 °C) | ≤ 5 mm | 1–3 mm |

| Cathodic Disbondment (28d, 80 °C) | ≤ 10 mm | 5–7 mm |

| Flexibility @ −30 °C | IGS‑M‑TP‑026 | No cracking @ 3.6° ppd |

| Hot‑Water Adhesion (28d, 80 °C) | < 10% area blistering | No delamination |

Standards & Compliance

Best Uses

© 2025 – All rights reserved – Powered by Ravak Agency