Peka‑Pro DL‑AS from Peka Chemie is a hybrid functional coating system combining the benefits of enhanced anti‑slip texture with anti‑static capability. This dual‑layer FBE system is designed for steel pipelines requiring a concrete weight coating (CWC) in environments where electrostatic charge buildup must be mitigated — for example, in flammable gas service or installations in dry climates where static could cause safety hazards.

The base corrosion‑resistant FBE primer (Peka‑Pro Pr) provides long‑term cathodic disbondment resistance, while the outer anti‑slip / anti‑static layer improves shear resistance between the pipe and CWC, ensuring secure placement and preventing micro‑movement under load or buoyancy forces.

Key Advantages

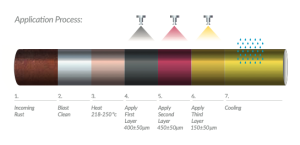

Application Process

Technical Highlights (Representative values)

| Property | Standard | Result |

|---|---|---|

| Surface Resistivity | IEC 60093 | ≤ 10⁹ Ω (Static dissipative range) |

| Friction Coefficient | CSA Z245.20‑22 (System 2C) | Meets / exceeds requirement |

| Cathodic Disbondment (20 °C) | CSA Z245.20‑22 | ≤ 5 mm |

| Hot‑Water Adhesion | CSA Z245.20‑22 | Pass |

| Impact Resistance | CSA Z245.20‑22 | Pass |

| Flexibility @ −30 °C | CSA Z245.20‑22 | No cracking |

Standards & Compliance

Best Uses

© 2025 – All rights reserved – Powered by Ravak Agency