FBE for high service temperature - PEKA Pro HT 140

If you need FBE for high service temperature up to 140°C, with excellent adhesion, long term cathodic disbonding resistance (28d, 95°C, -1.5V) and outstanding flexibility and impact even at -30°C, we recommend you PEKA Pro-HT series, especially PEKA Pro-HT 140.

Peka-Pro HT

Peka Chemie has introduced a new Fusion Bonded Epoxy (FBE) technology Peka-Pro HT120 and Peka-Pro HT140. Peka-Pro HT protects oil and gas pipelines against corrosion while they operate at high temperatures.

Peka-Pro HT120 and Peka-Pro HT140 products are a one-part, heat curable thermosetting epoxy powder designed as a stand-alone or as the corrosion coating for a dual layer FBE and multilayer polyolefin system for the corrosion protection of pipe. These new FBE coatings have excellent thermal properties that protect natural gas and crude oil pipes against corrosion.

Peka-Pro HT120 and Peka-Pro HT140 can operate up to 115⁰C and 135⁰C respectively as a stand-alone coatings.

Product Description

Peka-Pro HT-140 series is a thermosetting epoxy powder designed as a stand-alone, primer for three layer polyolefin system (3-LPE) and also as a first layer for dual layer FBE system for underground and subsea pipeline protection that operate in high temperature service. It has outstanding high temperature Cathodic disbonding, hot water resistance and excellent adhesion even in severe soil and environment condition. Peka-Pro HT-140 series shows excellent flexibility even at –30⁰C. Peka-Pro HT140 when properly applied, should perform in a satisfactory manner on pipelines operating between –73⁰C to 135⁰C. However it is difficult to accurately predict field performance from the laboratory data due to the wide variation in actual field conditions.

Uses

-

Gas & Oil pipelines

-

Water pipelines

Power Properties

|

Specific Gravity |

CSA-Z245.20 (Clause 12.6) |

1.35 ± 0.05 gr/cm3 |

|

Color |

RAL K7 |

Pink |

|

Particle Size |

CSA-Z245.20 (Clause 12.5) |

Max 3% > 150 µm Max 0.2% > 250 µm |

|

Gel time @ 205°C |

CSA-Z245.20 (Clause 12.2) |

10-30 sec |

|

Thermal Characteristics |

CSA-Z245.20 (Clause 12.7) |

Tg1(mid)= 55-75°C Tg2(mid)= 135-145⁰C ΔH= 120-160 J/g |

|

Moisture Content |

CSA-Z245.20 (Clause 12.3) |

< 0.5% |

|

Cure Time @ 232°C |

CSA-Z245.20 (Clause 12.1) |

< 70 sec |

Film Properties

|

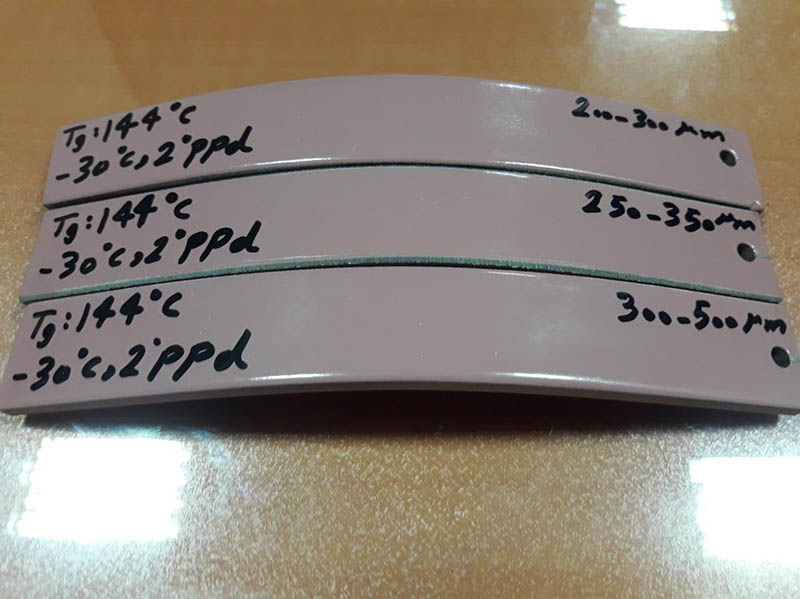

Flexibility |

CSA-Z245.20 (Clause 12.11) |

2° ppd at -30° C (-22° F) |

|

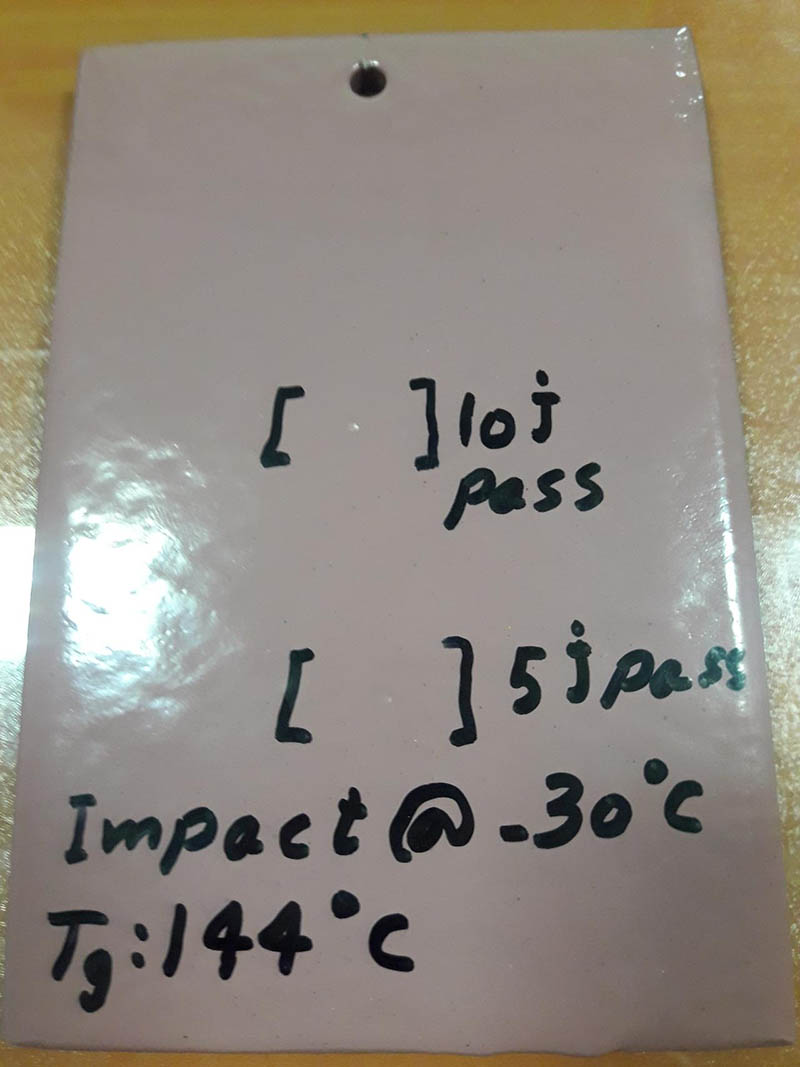

Impact Resistance |

CSA-Z245.20 (Clause 12.12) |

> 7 J at -30° C (-22° F) |

|

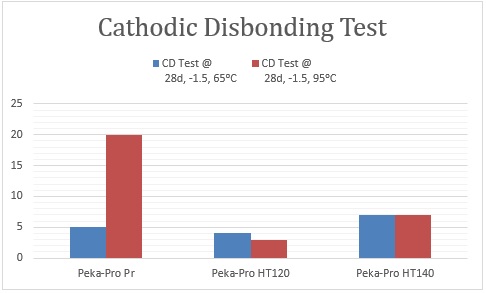

Cathodic Disbondment |

CSA-Z245.20 (Clause 12.8) |

1-3 mm @ 24 hrs, -3.5 V, 65°C±3°C 1-4 mm @ 28 days, -1.5 V, 20⁰C±3°C 3-9 mm @ 28 days, -1.5 V, 95°C±3°C |

|

Hot Water Adhesion |

CSA-Z245.20 (Clause 12.14) |

No disbonding and delamination @ 28 days, 95°C±3°C 24 hrs, 95°C±3°C |

|

Cross Section Porosity |

CSA-Z245.20 (Clause 12.10) |

Rating 1-3 |

|

Interface Porosity |

CSA-Z245.20 (Clause 12.10) |

Rating 1-3 |

|

Strained coating, Cathodic Disbondment 28 d, 20°C±3°C, −1,5 V |

CSA-Z245.20 (Clause 12.13) |

No cracking and disbonding |

Cathodic Disbondment & Flexibility

|

Peka-Pro HT-140 |

Thickness: 300 µm |

|

Test Methods |

CSA-Z245.20 (Clause 12.8) CSA-Z245.20 (Clause 12.11) |

|

Test Condition and Results |

28 days, -1.5 V, 95°C 3mm Flexibility @ -30⁰C, 2⁰ppd No Cracking |